BOST PROJECT

Proposed BOST project In Tumaco, Columbia

General Information:

- To be classified as no 1 marine terminal

- Coast Guard Approved Marine Emergency Response Plan

- Fully Computerised

Location:

Land: 150 acres based in Tumaco, Colombia

1. SCOPE

Result of UNCO UNITED S.A. technical inspection to the ECOPETROL'S TERMINAL in TUMACO during May 19th, 2006.

2. INTRODUCTION

The Tumaco Terminal started the operation at may 10th, 1969. It is the end station of OTA pipeline.

This Terminal receives crude from Estatiom-1 , The OTA (Transandino pipeline) is located along the Putumayo and Nariño departments.

Main Characteristics:

| LONG: | 305 KM |

| WORKING PRESSURE: | 1160 PSI |

| LINE CAPACITY: | 48KBOPD |

| CURRENT PUMP FLOW RATE: | 900.000 BBLS |

| STORAGE CAPACITY: | 305 KM |

| PUMPS: | 2 x 950 HP |

| PUMP STATION: | ORITO,GUAMUEZ & ARIZALES |

| REDUCE PRESSURE STATION: | ALTO, GUABO, JUNIN & GUAYACANA |

The Pipeline was built with diameters of 10, 14 y 18 inches. There are four pump stations: Orito, Guamues, Alisales and the Tumaco Terminal. There are also four reduce pressure stations: El Alto, Guabo, Junín and Guayacana. In Orito also landing others secondary pipelines that transport other crude produced in the zone:

West: Pipeline Churuyaco Orito (OCHO) 6 inches pipeline

South: pipeline San Miguel Orito (OSO) - 12 inches pipeline

North - East: pipeline Mansoyá Orito (OMO) - 6 inches pipeline

3. OFF SHORE TERMINAL

Proposed Bulk Oil Tank Farm:

- 60 tanks ranging from 60 Cubic metres to 27,000 Cubic metres.

- Working capacity of 5,500,000 barrels for crude and finished products.

Dock Lines & Pipe Line:

Two twelve inch dock line with a controlled ten-inch shoreline connected to the refineries.

Berth:

At least 244 metres (800ft) dock face length with a minimum of 35 feet of fresh water drafter.

Blending:

- Full blending of products, dyes and additives

- U.S. and Canadian Government specifications

Fire Protection:

- Rack protected by water sprinkler systems

- Tank farm protected by foam system and private hydrant system

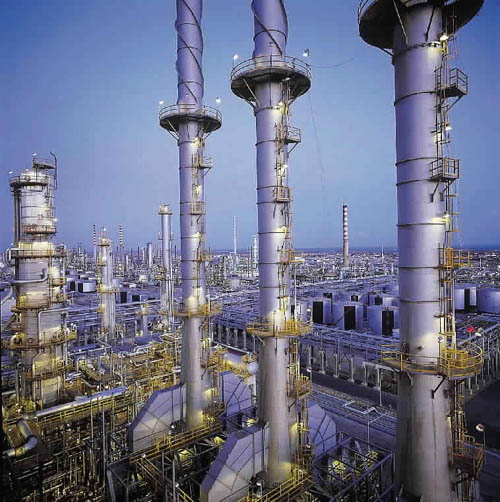

4. OIL REFINERY SPECIFICATIONS:

Capacity: Total of 100,000 barrels/day comprising of two (2) 50,000 barrels/day

Crude Supply: Venezuela, Bonny Light and Southern Blend, West Texas

Input Crude per year: 35,000,000

Output (product) per year: 33,586,000 or better

Products:

Gasoline 93 RON

Gasoline 87 RON

Kerosene

Diesel

Jet a Fuel

LPG

Fuel Oil

The complex will process Ecuador, Colombia, Venezuelan, West Africans or USGC crude slates, and make a full slate of clean fuels suitable for distribution in North America and China. We intend to place two processing trains with a total capacity of 100,000B/D. The total facility will include Berth and Docking Facilities, and 5 million barrels of working inventory for Crude and Product Tankage.

However, Fluor Daniel has reviewed Unco United business plan and has provided its recommendations and the investment team has agreed to consider a Phased Development Approach which minimizes pre-investment of capital by providing a progressively more accurate estimate of the project cost as the project scope and execution is defined. This staged approach facilitates timely decisions on project scope reductions and execution strategies, as well as verifying the over economic viability of the project. In practice the phased approach ensures that the project definition (scope of work, execution plan and cost) is consistent with the Business Plan objectives at the completion of each Phase of the evaluation before approving additional funds for further project development.

The first phase will be confirmation of a Feasibility Study estimated last six to eight weeks, and will produce a process configuration, overall material balance, and product yield slate. The Feasibility Study will also produce a cost estimate typically accurate to within +/- 30%.

The second phase of the project would continue engineering through a Front End Engineering Design stage (FEED), and would require 10-12 months to complete. The completion of the FEED phase will result in a detailed estimate (typically accurate to within +/- 10%) and the design basis deliverables to support detailed engineering.

The following provides an overview of the execution plan for both the Feasibility Study and the FEED design phase.

Following a capital commitment to the project, the FEED phase will follow the Feasibility Study. In this phase the requirements of each process unit will be reviewed, and licensor advice for the available technology will be sought. The available technologies will be integrated into a set of process units that will fit together to accomplish the goals of the plant at the lowest combined total installed capital and operating cost. The resulting effort will produce a design specification for the plant suitable for a detailed cost estimate, which historically provides an accuracy range of +/-10%.

In the Feasibility Study, the plant will be designed in a basic building block format using the requested Crude oil feed(s), and making the requested distribution of finished products. A refining model will be utilized that will determine the size and type of the various processing units required to complete the total refinery. Those refining units will include higher technology licensed units (4-6), several simpler non-licensed units, (3-4), a number of refining support units (4-6), and key environmental units needed to protect the local area. The refining model will show the rates and properties of the many streams that will connect from the processing units. A blend summary will give the result of the complete refining operation and show the mass, volume, and key specifications of the blended products (LNG and LPG, MoGas, Distillates, and Fuel Oil). The byproduct streams (e.g. molten sulfur) will also be identified along with their qualities and production rates.

Estimated Construction Costs:

The estimated Construction Costs is in excess of US$1,500,000,000.00.

5. MARKET CONDITIONS:

Regarding market conditions, the refinery over the coast of the Pacific Ocean has easy and low transportation costs to the second largest industrial city of Colombia consuming 30% of all fuels refined in Colombia.

It is Unco United S.A intention to finalise in the meantime, working agreement with ecopetrol over the current Tank Farm consisting of 900,000bbl of South Blend to store Crude imports and or domestic contributions and to use the port facilities to re-export crude and finished products and later to play a part in the expansion program. The South Blend is a mixture 36% Orito and 64% of Oriente crude from Ecuador and or 100% of Orito.

Clearly, the main issue with Crude Oil Prices is not a matter of Supply and Demand; it is simply a shortage of refining capacity worldwide. Over the past 27-30 years, no new refineries have been built in South America. Revamping yes! The fuel supply shortage at the beginning of year 2000 was 5.7 million barrels per day of gasoline and diesel fuel in South America.